UV technology offers a promising and pragmatic solution because it can significantly enhance food safety with minimal adverse effects on the environment and the quality of foods.

In her eye-opening documentary “Poisoned,” filmmaker Stephanie Soechtig shined a light on the alarming extent of contamination in the American food industry, with everyday grocery items from lettuce to chicken breast—even cookie dough—often tainted by dangerous levels of bacteria.

It’s not surprising, necessarily. Romaine lettuce is frequently infected by E. coli O157 carried in irrigation water. Salmonella and Campylobacter that often contaminate chicken breasts are prevalent in the fecal matter on chicken farms. And the cookie dough? Raw flour can carry harmful bacteria like E. coli, which remain alive even after baking. Raw or undercooked eggs can also introduce Salmonella into the dough, posing a risk to people who like a bite of raw dough while baking or who don’t bake their cookies until well done.

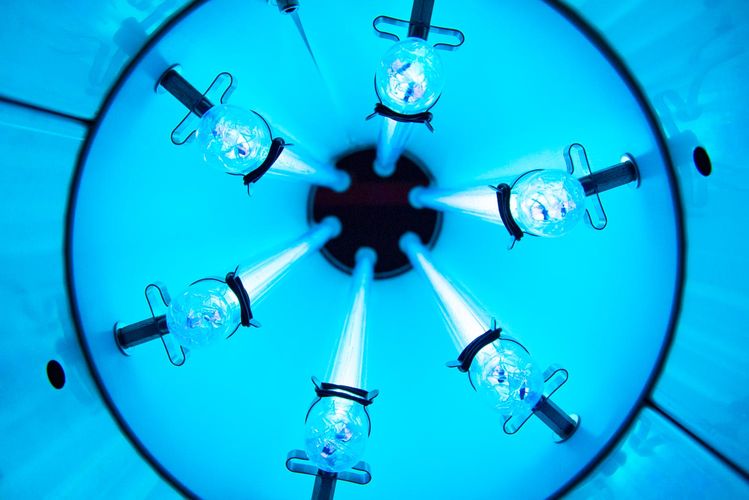

These contamination vectors are built into the process and are hard to eliminate. That’s why, in the U.S. alone, a staggering 48 million people a year fall victim to food-borne illnesses. It’s also why we need innovative solutions. One of the best is ultraviolet technology. By harnessing the power of UV light—capable of killing harmful bacteria and pathogens in food items of all types—the food industry can markedly reduce the prevalence and severity of food-related illnesses.

A safe and versatile solution

UV technology for food and beverage offers a promising and pragmatic solution because it can significantly enhance food safety with minimal adverse effects on the environment and the quality of foods.

One vital step toward improving food safety is treating irrigation water, a common source of contamination on farms. Among the disinfection methods available, UV technology is an ideal choice. Unlike chlorine, which can negatively impact plant health and the environment, UV technology provides a powerful yet safe means of eliminating pathogens from the water. By effectively neutralizing harmful microorganisms, UV treatment ensures that irrigation water is made clean for agricultural use.

UV technology can also be used in food processing plants as a surface disinfectant for conveyor belts to curb the spread of pathogens. As highlighted in Soechtig’s documentary, this is where a lot of cross-contamination happens. It only takes one tainted batch to spoil the rest due to the surface-to-surface transfer of pathogens.

Let’s consider a scenario in which a worker cuts up a chicken tainted with Salmonella. As highlighted in Soechtig’s film, a single contaminated bird can contaminate an entire production line. Implementing UV surface disinfection measures here would act as a robust barrier against that contamination.

The same applies to fruit and vegetable processing. For instance, the outer surface of a cantaloupe is a porous texture and provides numerous crevices where bacteria can hide and thrive. Addressing this contamination is a challenge because these fruits might be irrigated with tainted water. So incorporating an additional disinfection step that includes UV light makes good sense.

UV technology can even be used to disinfect the packaging of, say, raw poultry. By ensuring that the packaging material is free from harmful microorganisms, UV disinfection offers another layer of protection that enhances the safety and quality of the food product throughout its journey— from the point of production to the consumer’s doorstep.

Addressing contamination at its source

Effective management of harmful pathogens requires a dual approach centered around disinfection and source-level regulations. The ultimate goal is to prevent pathogens from coming into contact with food products at the outset. However, the current regulatory framework is somewhat limited. In the farm environment, for example, the regulations primarily rely on periodic testing by growers to identify the presence of pathogens like E. coli in their water supply. These tests are conducted on an infrequent basis, often monthly or just quarterly. For instance, Food Safety Modernization Act regulations in the U.S. rely on periodic, highly infrequent micro tests of the source water.

To enhance the safety of food products, a shift toward more proactive and real-time monitoring mechanisms is needed as opposed to the conventional practice of collecting grab samples intermittently. UV treatment is a promising solution here, offering valuable insight into water-quality variations. Through internet-connected sensors, UV technology can monitor the water and treat it, actively identifying fluctuations in water quality and ensuring a swift response to any potential contaminants.

Indeed, by installing UV, growers can ensure greater regulatory compliance and higher quality food. It wouldn’t be a surprise to see large food producers like Fresh Express, Taylor Farms, or Dole offer a premium to growers who take these actions; in the same way, dairy producers often pay a premium to farmers who consistently deliver milk with a lower microbial count.

By addressing contamination concerns at the source, namely at farms and production facilities, UV technology offers a powerful tool to intercept pathogens before they have a chance to spread down the supply chain. This approach significantly reduces the likelihood of cross-contamination and subsequent food-borne outbreaks.

Final takeaway

A key advantage of UV technology is its potential to limit reliance on reactive measures downstream, such as product recalls and treatment of food-borne illnesses. Instead of dealing with the consequences of contamination after the fact, the integration of UV technology focuses on preventing the issue at its source. This protects public health and bolsters consumers’ confidence in the food they purchase, leading to stronger brand loyalty and a more resilient food industry.

Share: