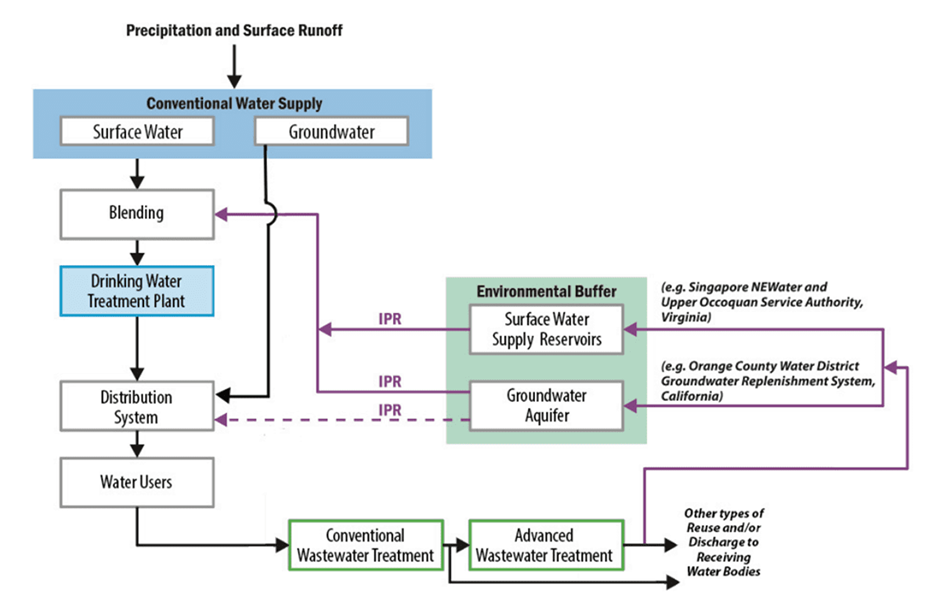

Indirect Potable Reuse (IPR) water is when reclaimed water goes to special buffers such as reservoirs and aquifers to be treated and used later for drinking water. IPR is useful when there is a readily available environmental buffer that is good quality and cost-efficient to maintain, protect, operate, and monitor.

There are currently 14 IPR projects that are operational in the USA. Of these, the largest facility is the Orange County Groundwater Replenishment System (GWRS) Advanced Water Treatment Facility reclaiming 100 million gallons of water daily (MGD). The facility appeared in 2008 and is the world’s largest. It produces reclaimed water using a three-step process (microfiltration, reverse osmosis, and ultraviolet light with hydrogen peroxide). Part of this water is then pumped into wells to act as a seawater intrusion barrier. Afterward, the remaining recharge groundwater basins in Anaheim. The GWRS is undergoing a $310 million final expansion to increase volume by 30 MGD of water.

Another large IPR project currently under study is the Hampton Roads Sanitation District’s SWIFT project in Virginia. Once developed, the plants could reclaim 120 MGD of water and inject it into the Potomac Aquifer for groundwater replenishment. This will limit saltwater intrusion and subsidence in the Tidewater area from Virginia Beach to Chesapeake and Newport News – Yorktown. Although no federal rules specifically refer to indirect potable water reuse, IPR facilities are well-regulated by state-provided rules. As of 2017, fourteen states (Arizona, California, Florida, Hawaii, Idaho, Massachusetts, Nevada, North Carolina, Oklahoma, Oregon, Pennsylvania, Texas, Virginia, and Washington) have clear Indirect Potable Water Reuse rules.

As mentioned earlier in this series on reclaimed water, reusing water for potable purposes has a significant cost. However, no matter the type of reuse (direct or indirect) and setup & operational costs involved, utilizing reclaimed water is highly cost-efficient in the long run. For example, the Orange County GWRS cost $481 million to set up initially. Since its inception, the plant has produced over 155 billion gallons of reclaimed water. The alternative cost to import from Northern California or the Colorado River would have been $318 million. Furthermore, the plant produces a water supply at nearly half the power required to pump water from Northern California – the energy equivalent to powering 30,000 homes annually.

The reused water is slowly gaining popularity globally. The advances in water treatment technologies have made it easy to implement Potable Reuse facilities. As the hurdles of cost and public perception give way, more states will begin to realize the actual value of reclaimed water.

Many wastewater facilities in Florida inject their treated effluent into aquifers for storage and future recovery after the water infiltrates and blends into the existing groundwater supplies in the Sunshine State. In Florida, they have effectively used treated effluent for irrigation and farming in the city and the country.

Further Reading:

Share: