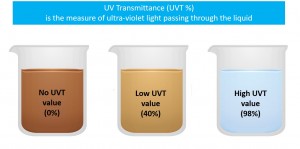

The value of accurately measuring UV Transmittance (UVT) when sizing a new UV disinfection system cannot be underestimated.

The value of accurately measuring UV Transmittance (UVT) when sizing a new UV disinfection system cannot be underestimated. Using an accurate UVT value during the sizing and operation of new UV equipment can directly impact both energy consumption and achieving the desired disinfection performance.

However, many customers that are considering new treatment equipment either don’t have access to the proper instrumentation or aren’t aware of the various options available to them for measuring the UVT of their water or fluid. There are several ways that customers can measure the UV Transmittance of their water or other fluid (such as sucrose or brine) to enable them to provide this information to the UV manufacturer, who can then make suitable recommendations on correct UV sizing:

Customers can send a small volume of fluid to a local lab to measure the transmittance of any fluid. Most labs will charge a fee for this service, depending on which parameters they can measure. The benefit of using the services of a lab to determine the UVT is that other important parameters relevant to the operation of a UV system can be measured simultaneously. These include the concentration of iron, manganese, total suspended solids (TSS), turbidity (NTU), and total organic carbon (TOC).

Reputable UV manufacturers will also be able to measure the transmittance of fluids at their facilities. Samples can be sent directly to the manufacturer, who will test the fluid in-house and often be able to provide quicker results than a third-party lab. Check with your UV manufacturer to find out if they offer this service.

A few instruments are available on the market for measuring UVT directly in the field. Because there is no need to send a sample away for testing, this can save both time and money. These instruments are handheld, portable devices that can accurately measure the transmittance of any fluid by collecting a small sample and testing it immediately at a customer’s site. Portable UVT instruments can be purchased from an instrumentation company or borrowed from a local distributor, who often has devices available for customer use. This testing method can save considerable time and produce an almost instant result.

For applications where the water quality can fluctuate seasonally or from batch to batch in an industrial process, installing a continuous UVT analyzer several months before purchasing a UV disinfection system could be beneficial. A UVT analyzer trending report available before equipment purchase will help to understand the minimum and maximum UVT levels rather than looking at the result of a one-off sample. This is particularly important for treatment applications with significant flow rates, where the investment in UV disinfection equipment could be hundreds of thousands of dollars.

Regardless of the UVT testing method chosen, providing actual UVT test results will give the manufacturer a proper understanding of water quality, helping them correctly size the new UV system.

Nuvonic

Date 01/02/2023

Share:

Notifications